Spindles - Novibra

75-100 words here for SEO about product line using keywords

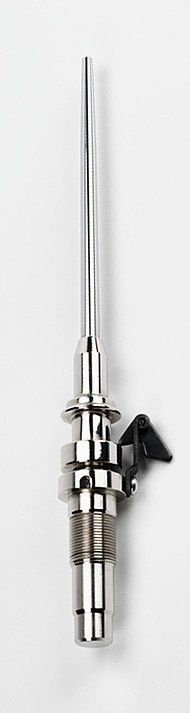

HPS 68

- for the modernization of existing machines

- for new installations

Description

- standard high speed spindle

- standard Novibra design with one piece insert and two bearing levels

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- high quality, low vibration, long life

- good running performance, even in cases of extreme imbalance of the cops

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- supplied with hook as well as with internal lock (AV lock)

- standard spindle is equipped with spring clutches. On request it can be supplied also with centrifugal clutches

- standard spindle has ALU top part. Bare blade type also possible (see chapter Bare blade)

Application

- recommended for spinning Ne 14 – 100

- recommended speed up to 20 000 RPM reflects the noise level requirements

- can be supplied for each type of ring spinning machine

Advantages

- low vibration

- low noise level

- low energy consumption

- long lubricating cycle

- low maintenance

- long operating life time

NASA HPS 68

- for the modernization of existing machines

- for new installations

Description

- new standard for high speed spinning

- Novibra one piece insert design two bearing levels

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- double damped spindle for maximum vibration absorption at high speed

- high quality, low vibration, long life

- good running performance, even in cases of extreme imbalance of the cops

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- supplied with hook as well as with internal lock (AV lock)

- standard type is with spring clutches but can be supplied also with centrifugal clutches

- spindle has ALU top part

Application

- recommended for spinning Ne 14 and above

- suitable for highest speed

- recommended for speeds up to 30 000 RPM

- can be supplied for each type of ring spinning machine

- most-used spindle in premium spinning machines

- standard spindle for Rieter machines

Advantages

- same advantages as standard HPS 68.

In addition:

- even lower vibration than standard version

- even lower noise level than standard version

- superior dynamic performance

- Followed by text and pictures from leaflet

HPS 68/3

- for the modernization of existing machines

- for new installations

Description

The same features as standard HPS 68 spindle:

- standard Novibra design with one piece inset and two bearing levels

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- high quality, low vibration, long life

- good running performance, even in cases of extreme imbalance of the cops

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- supplied with hook as well as with internal lock (AV lock)

- standard type is with spring clutches but can be supplied also with centrifugal clutches

- spindle has ALU top part

In addition:

- Foot step bearing diameter 3 mm giving energy savings up to 3 watt per spindle compared with any other spindle in the market today

Application

The same features as HPS 68 spindle:

- recommended for spinning Ne 14 – 100

- recommended speed up to 20 000 RPM reflects the noise level requirements

In addition:

- Energy consumption reduction per spindle at the same speed, or increase of the spindle speed with the same energy consumption

- Thanks to excellent design adaptable to each ring spinning machine with autodoffer

Advantages

- low vibration

- low noise level

- low energy consumption

- long lubricating cycle

- low maintenance

- long operating life time

In addition:

- Even lower energy consumption than standard HPS 68 spindle

NASA HPS 68/3

- for the modernization of existing machines

- for new installations

Description

The same features as NASA HPS 68 spindle :

- standard Novibra design with one piece inset and two bearing levels

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- double damped spindle for maximum vibration absorption at high speed

- high quality, low vibration, long life

- good running performance, even in cases of extreme imbalance of the cops

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- supplied with hook as well as with internal lock (AV lock)

- standard type is with spring clutches but can be supplied also with centrifugal clutches

- spindle has ALU top part

In addition:

- Foot step bearing diameter 3 mm giving energy savings up to 3 watt per spindle compared with any other spindle in the market today

Application

The same features as NASA HPS 68 spindle:

- recommended for spinning Ne 14 and above

- suitable for highest speed

- recommended for speeds up to 30 000 RPM

- most-used spindle in premium spinning machines

- standard spindle for Rieter machines

In addition:

- Energy consumption reduction per spindle at the same speed, or increase of the spindle speed with the same energy consumption

- Thanks to excellent design adaptable to each ring spinning machine with autodoffer

- Advantages

- The same advantages as standard NASA HPS 68.

In addition:

Even lower energy consumption than NASA HPS 68 spindle

LENA

Description

- LENA stands for LE – low energy, NA – noise absorption. Energy saving spindle LENA has been designed for the highest speeds with the main goal of achieving lower energy consumption.

Application

- recommended for speeds up to 30 000 RPM

- for all material Ne30 and finer

- for tubes up to 210mm

Advantages

- energy saving in the average of 4 - 6% thanks to reduced wharve dia and lesser friction of smaller bearings (both neck bearing and footstep)

- the only spindle with 17,5mm wharve dia in the market

L HPS 68

- for the modernization of existing machines

- for new installations

Description

The same features as standard HPS 68 spindle:

- standard Novibra design with one piece insert and two bearing levels

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- high quality, low vibrations, long life

- good running performance, even in cases of extreme imbalances of the cops

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- supplied with hook as well as with internal lock (AV lock)

- standard spindle is equipped with spring clutches. On request it can be supplied also with centrifugal clutches

- standard spindle has ALU top part. Bare blade type also possible (see chapter Bare blade)

In addition:

- Longer and lowered sleeve giving harder damping

Application

- Recommended for spinning Ne 4,5 - 30

- Maximal speed up to 20 000 RPM but in practice depends on yarn count i.e. up to 16 000 RPM

- Recommended for longer tubes (220 – 280 mm)

- Can be supplied for each type of ring spinning machine

Advantages

- low vibration

- low noise level

- low energy consumption

- long lubricating cycle

- low maintenance

- long operating life time

CROCOdoff

- for the modernization of existing machines

- for new installations

Description:

- Crocodoff is a clamping device for autodoffing machines

- New CROCOdoff ensures improved cutting of the yarn and minimizes problems associated with automatic doffing and start up.

- CROCOdoff works automatically. Closing (yarn catching) and opening (yarn releasing) is ensured by spindle speed change

- Less than 270° of yarn underwinding eliminates cleaning of the yarn catching device.

Application:

- Well proven solution of clamping of the yarn for all standard materials from Ne 16 up to the finest ones

Advantages:

- opening and closing of cutting crown by centrifugal force

- no uncontroled yarn-end flying

- reduction of yarn breakage

- reduction of energy consumption

- clean yarn catching part (less cleaning)

- easy fixing and exchange of CROCOdoff crown on CROCOdoff spindles

Bare Blade HPS 68

- for the modernization of existing machines

- minimum wharve diameter of 18.5 mm for highest spindle speeds at minimum speeds of driving elements

- high quality, low vibration, long life

- maximum speed up to 16 000 RPM

- good running performance, even in cases of extreme imbalance of the cops

- high spindle speeds with almost no maintenance

- low energy consumption

- limitation of the spindle speed by the spinning process and not by the spindle bearing

- considerably extended lubrication intervals

- low noise level

LUBRICO

The LUBRICO lubrication device for spindles is used for the maintenanceof all kinds of spindle bolsters. It is suitable both for the first oil filling and subsequent oil changes of the spindle bolster. The device is mobile and can be easily operated by one person. The dimensions of the device allow its use even in narrow tender alleys.

The LUBRICO has its "onboard" energy. Therefore, it functions autonomously during considerable periods of time.

During the operation of the device, neither tangling electrical wires nor tiring and time-consuming manual pumping have to be contended with.

Top Roller MICRO SEAL

The top rollers manufactured by NOVIBRA are fitted with low-friction bearings with double seals which prevent the ingress of dust and lint. Due to the advanced design, they guarantee top performance with extended lubrication cycles.

Top Rollers for all applications

- for the replacement of Top Rollers on existing machines

- for new machine installations

- an outstanding precision-engineered product with superb operating performance

- incorporating high-capacity double-row ball bearings in each shell

- protected by unique MICRO-SEALS, which prevent any dust or fly from entering the bearing, at the same time not allowing any grease to escape

- the non-friction MICRO-SEALS do not create any power loss

- relubrication cycle after 100,000 operating hours